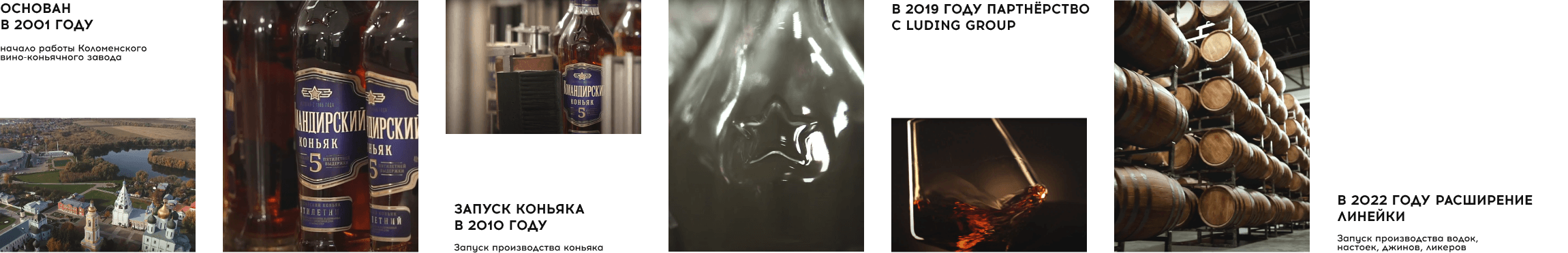

2022 > Kolomna Wine and Cognac Factory expanded its product line to include vodkas, liqueurs, gins, and other spirits

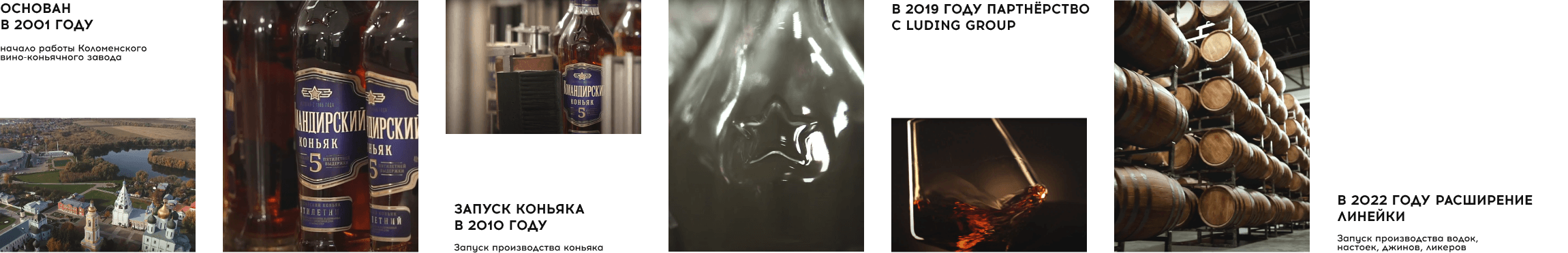

Cognac production was officially launched

Kolomna Wine and Cognac Factory was established

Cognac production was officially launched

Kolomna Wine and Cognac Factory was established

Kolomna Wine and Cognac Factory expanded its product line to include vodkas, liqueurs, gins, and other spirits

- Removing mechanical impurities through cleaning

- Enhancing the organoleptic properties through filtration using coconut charcoal

- Softening the water using ion exchange equipment

- Killing bacterias through UV treatment

- Purifying the water through reverse osmosis

This results in water which has a natural, pure taste with a soft texture, devoid of any neutral or distilled aftertaste.

Kolomna Wine and Cognac Factory's water purification process includes the following steps:

Before bottling, the cognac undergoes additional cleaning through fine cleaning filters of 10 and 1 micrometers.

Before bottling, the cognac undergoes additional cleaning through fine cleaning filters of 10 and 1 micrometers.

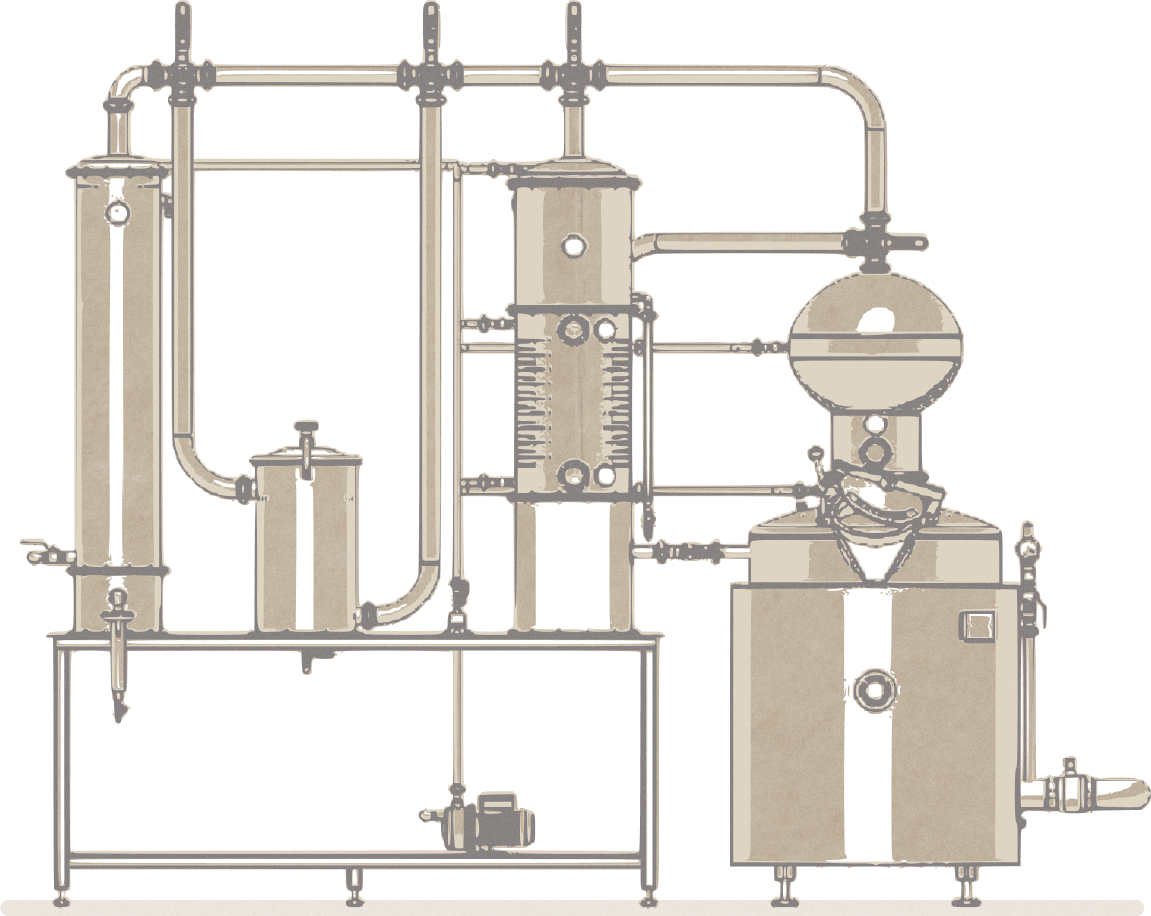

Kolomna Wine and Cognac Factory utilizes high-quality equipment for the production of our distillates. We use a copper alambik "Alexandra" made by industry-leading manufacturer, DES.This equipment features a copper boiler with a stainless steel water steam jacket, operating at a pressure of 0.5 bar and a temperature of 110°C.The concave cube, made of 99.9% pure electrolytic copper, ensures uniform mixing through centrifugal action. The 90 RPM mixer, placed diagonally, operates at significantly lower voltage, directing mass flow vertically for more efficient alcohol evaporation.Our distillation process also includes a Boiling Ball Helmet, which accelerates the steam flow to prevent overpressure and vacuum, and an epuration column with 18 copper plates for extended contact of alcohol vapors with copper and efficient separation into fractions. The reflux condenser, also made of 99.9% pure electrolytic copper, serves to partially condense vapors and return reflux to the column for a more complete separation of the mixture.

To obtain alcohol from grains and fruits, we use the Boiling Ball which provides an accelerated flow of steam during the distillation process and prevents overpressure, underpressure or vacuum if the steam does not have sufficient inertia.

The distillation column contains a chamber consisting of 18 copper plates. It provides extended contact of alcohol vapors with copper and divides them into fractions.

A flow-through reflux column made of 99.9% pure electrolytic copper partially condenses the vapor leaving the distillation column and returns the phlegm to the column for better separation of the mixture into fractions.

140 411, Russia

info@kvkz-spirits.ru

export@kvkz-spirits.ru

export@kvkz-spirits.ru

CONTACT